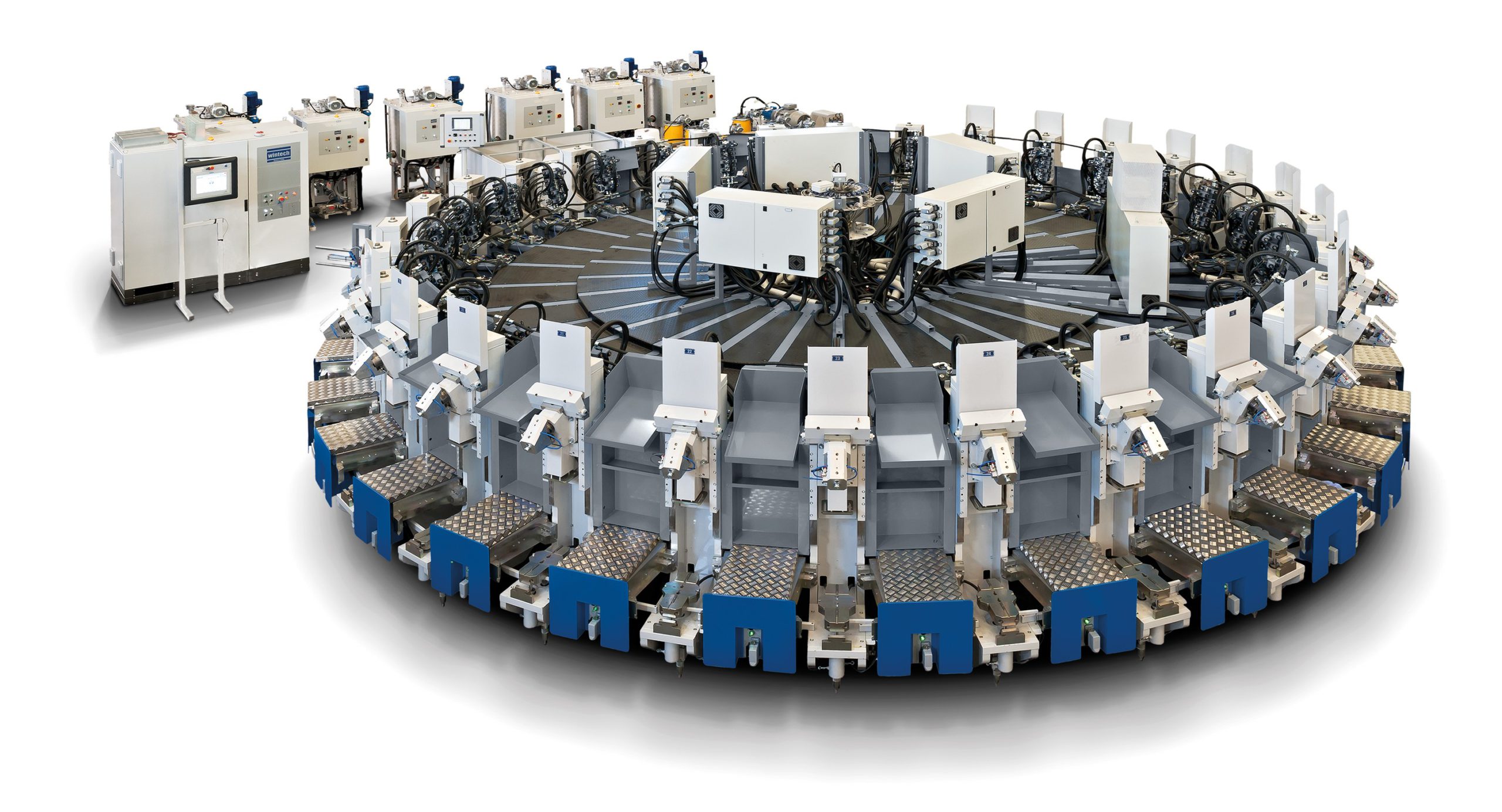

WINSHOES 201

WINSHOES 201

Macchina ad iniezione diretta su tomaia a 18,24 o 30 stazioni per la produzione di scarpe mono o bi densità in Poliuretano (PU)

Winshoes rappresenta una vera e propria innovazione specialmente per la nuova configurazione del portastampo, che permette un accesso totale all’area stampo, per tutte le operazioni sia manuali che robotiche, grazie alla corsa di apertura di 285 mm tra gli anelli.

Iniettore in bassa pressione con vite di miscelazione autopulente.

Testa predisposta per alloggiare fino a 7 unità ugello , materiali/colori con posizioni intercambiabili fra loro.

La macchina può essere completamente automatizzata integrando la robotica, anch’essa totalmente progettata da Wintech