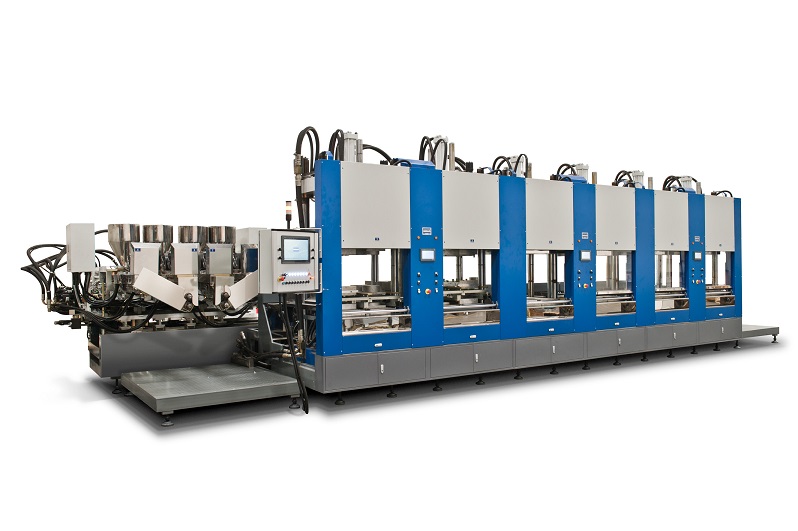

WE203BiEVA

WE203BiEVA

EVA BICOLOR has never been this simple.

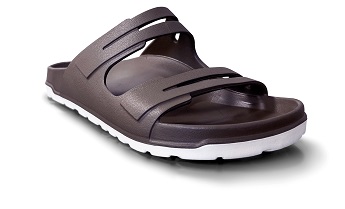

WE203BiEVA for molding bicolor EVA soles and sandals

The WE203BiEVA series is a range of machines designed for molding bicolor EVA soles, sandals, and galoshes. It features an operational configuration identical to the single-color machine, ensuring an unparalleled simplicity in bicolor molding.

Key features include:

– Large mold holder with a 430 mm opening, facilitating manual operations and ensuring ease of use and faster execution.

– Double-platen press with a hydro-mechanical, self-compensating differential closure system.

– Toggle opening located in the upper part of the mold holder, offering rapid opening and smooth movements.

– Linear configuration without confined operator zones, ensuring the same usability as the single-color machine.

A technological leap in efficiency and sustainability

The complete elimination of injection sprues marks a significant technological advancement, reducing material waste by 10-15%. This innovation delivers substantial benefits in terms of productivity and sustainability.

Main benefits:

– Zero material waste: The total elimination of sprues means fewer scraps to dispose of or recycle.

– Reduced cleaning times: The optimized process makes mold maintenance quicker and simpler.

– Smoother and more reliable process: Traditional challenges in bicolor EVA processing are completely resolved.

With WE203BiEVA, simplicity and efficiency redefine the standards of bicolor EVA molding.

News

News