BORADUE

BORADUE

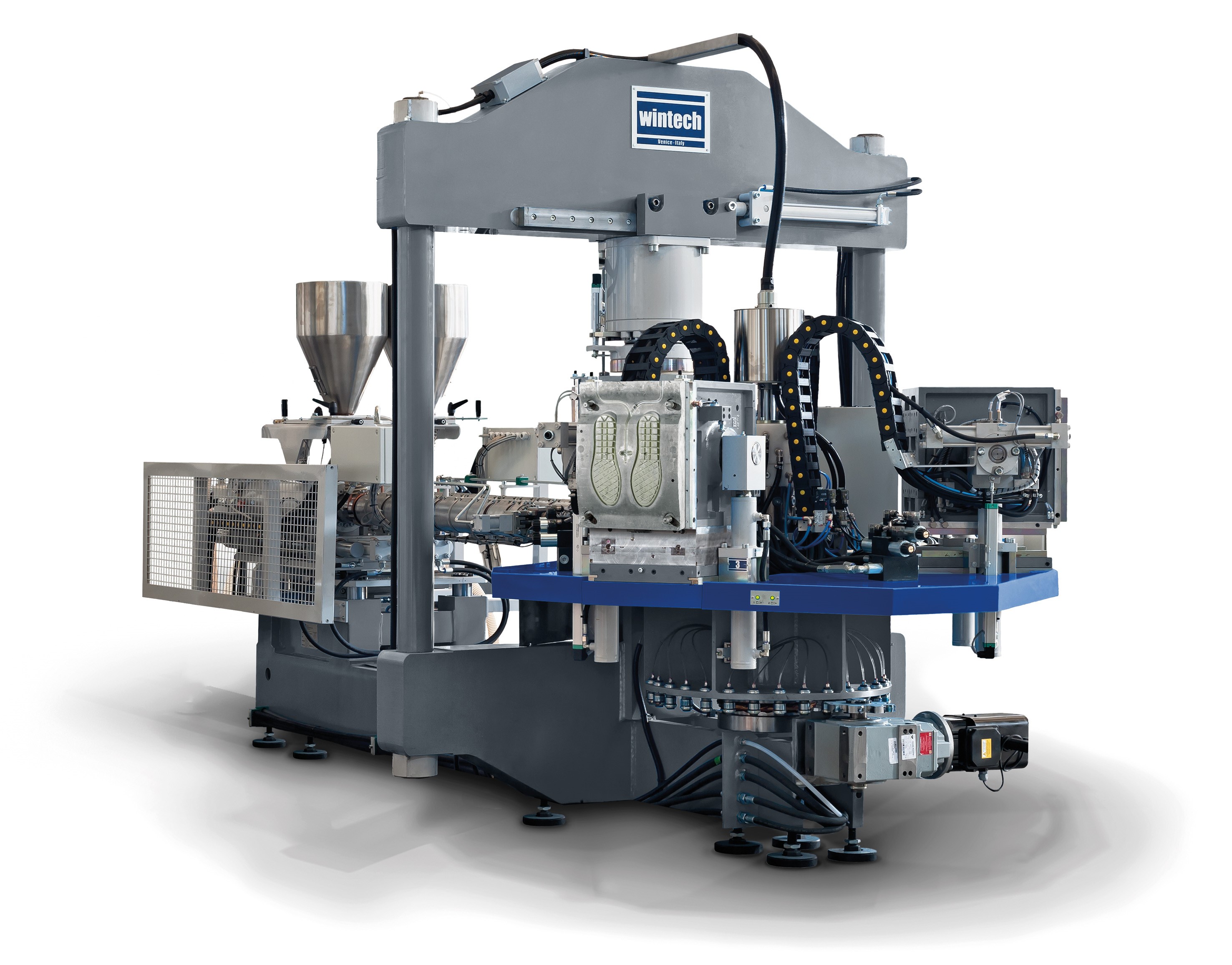

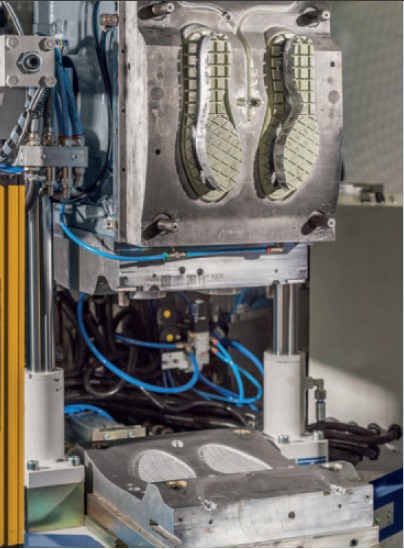

Compact flexible 3 stations rotary machine for the production of two-color soles in thermoplastic materials

Two working programs for an extreme production flexibility

– under press interchange cycle

– two laps cycle for extra cooling

The two working programs allow to choose the best productive cycle based on the final product, material to be injected, molds, different cooling times, keeping the high output thanks to the rotary configuration, eliminating the downtimes of the static machines.

Key Points

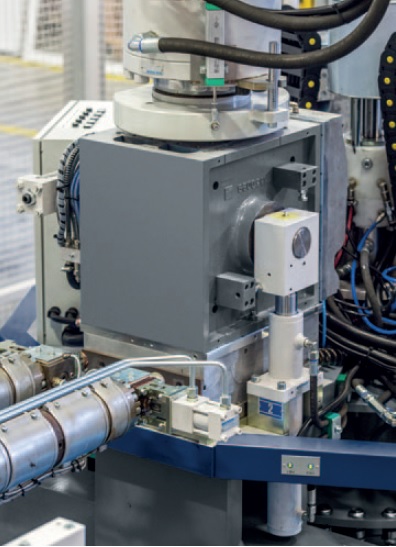

- Electric rotation for maximum speed on rotation

- Each station is independent on every injection parameters

- Cooling on all faces of the mold holder: base and the two covers

- Digital warehouse with saving of the injection parameters for each mould

- Injection screws with non-return valve for perfect management of injection volumes

- Automatic positioning of the injectors for variable injection heights

- Injection group translation for central injection